In 2005, Chinese nuclear R&D planning officials envisioned a so-called three-step scenario for the development of China’s nuclear energy program. This has served as an official point of reference throughout the 2010s including in most recent years in the Standing Committee of the State Council of Ministers.63 The strategy was first openly brought forth in the Medium- and Long-Term Program for Science and Technology Development Plan for 2006 to 2020, which called for China to concentrate on using PWRs through 2020, inaugurate a transition from PWRs to fast breeder reactors from 2020 through 2050, and, beginning about mid-century, add nuclear fusion reactors to its mix of thermal and fast reactors.64

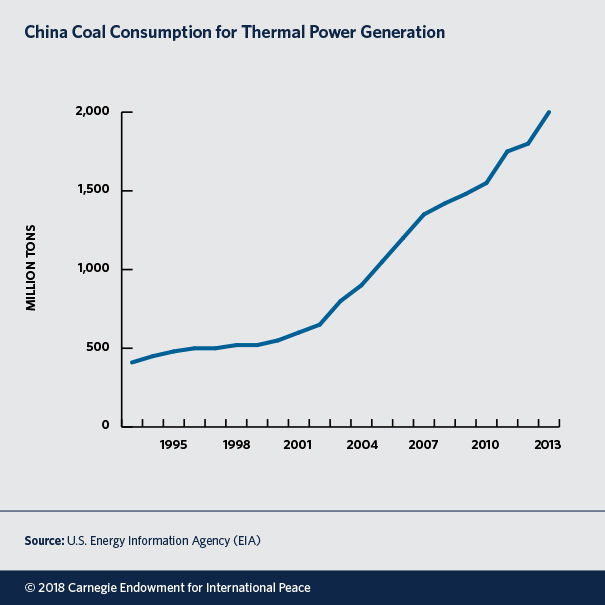

China also prepared a Medium- and Long-Term Plan for Development of Nuclear Energy in 2005. Informed by the strategic considerations discussed above, it reflected both the three-step strategy and then premier Wen’s 2005 decision to speed up nuclear power plant construction. Accordingly, this nuclear energy plan concluded that for China to reduce pollution and generate enough power, it must steamroll production of nuclear fission energy through 2050.

Specifically, by 2020, China should have an installed nuclear power generating capacity of 40 GWe (subsequently raised to 70 GWe and then lowered to 58 GWe), representing 4 percent of China’s total installed power generating capacity. The document spells out that most of the added reactors would be PWRs, and that operation of these units would result in a large inventory of spent fuel and contribute to the long-term depletion of uranium resources. Anticipating uranium becoming scarce and expensive, China would commission the CEFR and set up bigger fast reactors, including a 1,000–1,500 MWe unit by 2025. By 2050, China’s nuclear capacity, based on PWRs and fast reactors, would be between 120 GWe (a low estimate where nuclear power would account for 10 percent of China’s projected power generating capacity) and 360 GWe (a high estimate with a 30 percent nuclear capacity share). During the 2020s, China would construct a test fusion reactor, followed in 2040–2050 by an initial fusion power reactor, before transitioning to the third stage, when fusion reactors would complement fast reactors in the second half of the twenty-first century.65

Future Reprocessing Plants and Fast Reactors

When R&D scientists in the 1980s urged the government to include reprocessing and the fast reactor in its 863 Program, they also proposed industrial-scale follow-on projects, supported by strategic narratives. China has erected a pilot breeder and a pilot reprocessing plant, and during 2016 and 2017 made further decisions in favor of construction during the 2020s and 2030s of industrial-scale reprocessing plants and power-generating fast reactors.

Fast Breeder Reactor

Upon completion of the CEFR, debate began over the size of a second breeder reactor. The choice was between a 600-MWe reactor and a bigger unit rated at 1,000 MWe or higher. Factors in the decision included China’s relative lack of experience with fast reactors and the future of China’s cooperation with Russia, which had greatly contributed to the CEFR project.

Since the early 2000s, China and Russia had discussed possible construction of one or two Russian BN-800 fast breeder reactors at a site in Fujian Province on China’s east coast. In October 2009, an agreement was signed between CIAE, CNNC, and Russian vendor Atomstroyexport.66 The project was shelved for undisclosed reasons. According to Chinese sources, the 800-MWe Russian reactor could not be easily accommodated by a Chinese nuclear industry that had been set up to produce equipment for generating units rated at 600 MWe.67

Accordingly, during 2017, China prepared to break ground on a 600-MWe fast reactor construction project at the Xiapu site in Fujian Province by 2018, with the aim of completing the work by 2023. This was, to say the least, an ambitious schedule for a first-of-its-kind advanced power reactor design built in China. In mid-2017, the site was populated by personnel preparing for construction to get underway.68 In December 2017, China officially announced that construction had begun.69

Absent authoritative public information about this project during recent years, some speculative media reports claimed that CNNC, working with CIAE and the U.S. firm TerraPower, would begin constructing a 600-MWe fast reactor in Fujian using a TerraPower design.70 The TerraPower concept, developed in part following past decades of fast reactor R&D at the Argonne National Laboratory in the United States, requires metallic reactor fuel; in its cooperation with Russia in the CEFR, CIAE had focused instead on future use of oxide fuel. However, some of the media reports claimed that CIAE would nonetheless be in charge of fuel development for the TerraPower unit.

CIAE and CNNC instead prioritized an oxide-fueled 600-MWe breeder in Fujian, called the China Demonstration Fast Reactor (CDFR) or CFR-600. They promoted this project to the government to demonstrate equipment design and manufacture, power generation, system reliability, economic performance, and the development of technical standards and codes.71 The CFR-600 concept design was completed in 2014, but the detailed design was not settled until 2017.72 The project is described by some open sources as majority-controlled by CNNC, with other shares held by the China Yangtze Power Company, the Huaneng Nuclear Power Development Corp, and the Xiapu State-Owned Assets Group, an investment company.73

In recent years, CIAE proposed following up the 600-MWe reactor in about 2030 with the first of a series of commercial breeders called CCFR-B, or an alternative version called CCFR-T meant to demonstrate transmutation. In either case, this scheme calls for the construction of many “high-breeding” fast reactors through 2050, which would “replace fossil fuels” between 2050 and 2100.74 The December 2017 announcement of construction starting on the 600-MWe fast reactor at Xiapu included information that a bigger reactor, rated between 1,000 MWe and 1,200 MWe, may be approved by the central government in 2020. This implies that construction of this unit might begin in 2028, with the reactor ready to operate in 2034.75 Some speculative media sources claim that instead a 600-MWe TerraPower unit may be built after the CFR-600.

During the last decade, CIAE projected that, based on expected growth in electricity demand and the need for non-carbon-emitting power sources, China might in the long term construct fast neutron reactors with an electricity generating capacity between 70 GWe and 200 GWe, compared to a forecast total nuclear capacity in China by 2050 of 400 GWe.76 Some of CIAE’s shorter-term projections for fast reactor construction have been just as stunningly optimistic, calling for a 20-percent fast reactor share of a projected 250-GWe total nuclear capacity in China by 2050.77 CIAE’s breeder reactor vision foresees China building fast reactors at such a rate by the end of the twenty-first century that, by the second half of the twenty-second century, over 100 units would be operating in the country, permitting “nuclear power to replace fossil fuel.” The Chinese government has not endorsed any of these plans.

When China began prioritizing the breeder in the mid-1980s, a number of countries—France, Germany, Japan, the Soviet Union, the UK, and the United States—had already launched fast breeder programs two or three decades before and operated experimental or pilot fast reactors for a decade or more. By the 1980s, these countries were preparing to set up industrial-scale units rated between 300 MWe and 1,200 MWe, to demonstrate that the technology could be used to generate electricity reliably and economically.

China’s project was intended to tap the Soviet Union’s experience in the design and operation of four fast reactors—BR-5, BOR-60, BN-350, and BN-600. China’s risk in doing this was modest and the potential benefits considerable, since China’s initial goal was limited to gaining enough knowledge to successfully implement a project for a small experimental reactor rated at 20-MWe. This project would replicate others’ previous efforts, incorporate their lessons learned, and, most importantly, include China in the field of advanced nuclear power countries having technology that offered the possibility of virtually unlimited future nuclear fuel supply.

The decisionmaking environment for the fast reactor is quite different today than three decades ago. During the intervening years, none of the above countries succeeded in building and then operating an industrial-scale demonstration fast reactor to produce electricity using plutonium fuel at a self-sustaining cost, and all encountered technical challenges, which translated in some cases into an erosion of political support. The most important issues were sodium fires, equipment and engineering problems, and severe accident concerns. The cumulative impact of these contributed to decisions by governments in France, Germany, Japan, the UK, and the United States not to license planned fast reactor construction projects and/or to prematurely close reactors that were licensed for operation. The record of technical issues that have daunted fast reactor programs since the mid-twentieth century includes the following:

- Steam generator integrity: Sodium reacts violently with air and even more so with water, and fast reactors have experienced very damaging sodium fires on occasions when liquid sodium leaked.78 A number of leaks and fires occurred in early-design steam generators in France, the UK, and Russia. Leaks were caused by steam generator manufacturing defects or by cracks in equipment caused by material fatigue and corrosion.

- Other sodium leaks and fires: Many of these leaks were small and were detected by periodic inspections, but larger ones include four leaks at BN-600 involving between 300 kilograms (kg) and 1,000 kg of sodium. A leak of 640 kg of sodium at Japan’s Monju unit resulted in a serious fire, which spread by dispersed sodium aerosols because sodium circuits were not emptied—the sodium containment was not fully inerted and ventilation systems failed to operate.79 Leaks were caused by faulty equipment design and by fabrication, materials-related issues, corrosion, and operator error.80

- Equipment, materials, and engineering issues: Defective design, inadequate materials, and faulty operating procedures have led to myriad problems in several reactors. Design flaws in some cases caused heat exchangers and pumps to fail. French regulators raised issues concerning the integrity of core support structures. Equipment immersed in sodium proved in some cases inaccessible to inspection, leading to maintenance problems and long outages. Material weakness led some equipment to crack when exposed to sodium for long periods. Control rods failed in reactors in Germany, France, and the UK due to deposits of oxidized sodium aerosols. Some critical equipment in several reactors was initially made with steels that proved vulnerable to cracking in welded hot areas and caused long repair outages. These materials were later replaced by others that are stronger and corrosion-resistant.81 Similar problems also challenged LWR development. For LWRs these were overcome only after improvements, backed by decades of operation at several hundred reactors, were made. It is possible that over time many or most of these issues faced by fast reactors might be solved, provided however that reactors accumulate sufficient operating experience.

- Incursions of air and impurities: Incursion leads to the formation of solid particulates and other compounds that cause harm by provoking secondary reactions and buildup of deposits. These can cause component damage, so limiting them is essential to assuring long component and system lifetimes and reliability. Fast reactors—SPX in France, PFR in the UK, and BN-600 in Russia—suffered incursion events between 1987 and 1991 that led to long outages. Today, sodium purification equipment is well developed and the risk of incursion might be less.

- Fuel integrity issues: A number of reactors in France, Germany, Russia, and the UK suffered cladding ruptures, especially during initial operation. In some cases, problems were caused by inappropriate austenitic steel used as cladding; in some other cases, they were caused by issues related to the geometry of fuel design. Integrity issues inhibited irradiation to high burnup levels desired for fast reactors. The most serious problems occurred during early years of fast reactor programs. These events have been reduced over time by better fuel design and the use of stronger materials. The basic problem is that burnup levels for sodium fast reactors are three or more times greater than for LWRs, and the fuel must withstand higher temperatures.82

Governments and industries have prioritized addressing the above issues to improve the safety, reliability, and performance of future fast reactors. In some cases, remedial actions were taken at operating reactors. A key area of development is fast reactor steam generator systems: in future reactors, these must be equipped for rapid hydrogen detection and, in that case, they must respond by promptly shutting down and depressurizing affected steam circuits. Future steam generators may also be outfitted with protective casings resistant to extreme sodium-water reactions; safety membranes may limit pressure increases in the case of a sodium-water event. In modern reactors, sodium leaks might be limited by the use of improved materials and by better welding of sodium-boundary equipment.

Beginning in the 1990s, implementation of some of these measures led to a significant reduction in sodium-water interactions at French and Russian reactors.83 But challenges remain: Some equipment and systems in future reactors may be designed to have double walls, but this could cause welding problems in critical components such as steam generators. Other proposed approaches to improve system integrity and safety, such as adding a reactor loop (for example, using molten salt), will likely prove too expensive.

Leaks and fires have prompted improvements in equipment design; operations procedures for sodium circuits; use of redundant leak detection systems; fire protection including emergency emptying of sodium circuits; compartmentalization of sodium areas to inert or cut off ambient air supply in the case of fire; and use of fire-resistant surface materials.

In light of experience, future reactors must be designed with new features: diversified safety systems to mitigate the risk of common-mode failures; improved cores that exclude or limit probability of core collapse leading to a serious accident;84 primary circuits limiting buildup of gas; and improved maintenance technology for equipment immersed in sodium, including ultrasonic instrumentation to facilitate inspection. To handle some accident scenarios, it will be necessary to be able to completely remove the reactor fuel load. Other safety challenges include seismic resistance, anti-flood measures, severe accident management, geometric stability of the core, and reliability of control rods.85

On balance, technical reliability is a major challenge standing in the way of a commercial future for this technology, including in China. In a few cases, and for limited periods, fast reactors have demonstrated a capacity factor (the ratio of actual electric power output over a period of time, compared to the output that would be achieved if the plant operated at full power rating without interruption) between 50 percent and 75 percent—but to compete with LWRs under market forces, a capacity factor of 90 percent may be necessary. Improving fuel, in-service maintenance, component reliability, and the reduction of sodium-related events will be paramount to achieve this. Most sodium leaks and fires have not strictly speaking been nuclear safety–significant events, but they have greatly contributed to low capacity factors during fast reactor operation.86 Experience with the Russian BN-600 suggests that greater reliability in future reactors may be possible: after thirty-five years of operation, the BN-600 has produced two-thirds of the electricity generated by all of the world’s nineteen fast reactors. It has performed at a capacity factor of 77 percent during the last two decades and its licensed lifetime may be extended to sixty years.87 The improvements in BN-600 operation are well-known to China’s breeder program through CIAE’s collaboration with Russian R&D institutions.

Industrial Reactor-Building Capacity

Should China go forward with plans to set up advanced nuclear power installations including industrial-scale fast reactors, these projects would be implemented by a nuclear industry that, without interruption since the early 1980s, has been aggressively developed and indigenized with Chinese government assistance and foreign technology inputs. Before 2030, China will likely have set up 100 nuclear power plants on its territory. Especially given China’s relatively low level of economic development until the 1980s, this feat is considerable. But it is not unprecedented. The United States built over 100 nuclear power reactors in about the same amount of time; France built almost sixty units, and Japan nearly that many, over the span of half a century.

Since the 1980s, China has organized its nuclear power industry around a small number of very big SOEs, chief of which are CNNC and China General Nuclear Power Group (CGN, formerly CGNPC). Each of these firms, particularly CNNC, has numerous subsidiaries and owns shares in still more companies, giving them great influence or, in some cases, direct control over most nuclear power investment and construction activity in China. Both CNNC and CGN are vertically integrated companies that invest in, build, and operate nuclear power plants. A third such company was established in 2015, when the State Nuclear Power Technology Corporation merged with China Power Investment Corporation, a leading Chinese utility company, to form the State Power Investment Corporation (SPIC). Until now, these firms have spearheaded all of China’s nuclear power plant construction. Nearly all the nuclear power plants they have built or are constructing are PWRs. Over time, China has succeeded in claiming control over intellectual property rights to this technology. After building nuclear power plants based on foreign technology its owners agreed to share, Chinese firms modified the technology and branded the results as Chinese intellectual property.

In step with the central government’s decisions in the late 1970s to invest in nuclear power and in the mid-2000s to accelerate nuclear power plant construction, China’s heavy industry has built up the capacity to make equipment needed for serial realization of multi-reactor nuclear power plant projects. Investment began during the 1980s to support construction of a line of PWRs that CNNC had pioneered with assistance from a number of foreign industry partners. When China began scaling up this infrastructure to meet the technical demands of bigger units, it encountered difficulties and had to invest more in forging, component manufacture, and quality control. In tandem with the 2005 decision to accelerate the pace of China’s nuclear power construction, five select state-owned power-engineering and heavy equipment–making companies spent $4.5 billion to build up their capacities.88 Today, these firms are equipped to annually produce the critical nuclear equipment (sufficient reactor pressure vessels, core internals, and control rod drive mechanisms)—and up to twenty-seven steam generators, thirty primary pumps, and fifteen turbine generators—to equip between eight and ten new nuclear power plants per year.89

Should it indefinitely sustain this industrial capacity, China would meet the requirements for a continued expansion of its installed nuclear capacity at all but the highest current projections through mid-century. Estimates from Chinese sources and organizations have varied widely about how much nuclear power capacity should be added during the next three to four decades. Attaining an installed nuclear capacity of 300 GWe by 2050—a baseline reference found in some Chinese studies—would mean adding about eight reactors per year until 2050.90 Considered solely on the basis of equipment-making firms’ current capacity, this might be feasible. Compared to the United States, where thirty utility companies and seven vendor firms built a variety of plant designs at a rate of five units per year, China would benefit from ongoing industry standardization and consolidation.

China has also invested in transitioning from PWRs to fast reactors by 2050. Since the late 1960s, CIAE, in cooperation with Russian industry, has been working on fast reactor neutron behavior and thermohydraulics, development of sodium-handling equipment, reactor materials, and fuel. China also set up three dozen experimental facilities and testing circuits for fast reactor R&D, many concerned with the critical field of sodium management. All told, over 100 Chinese institutions are now involved in efforts to set up an industrial-scale fast reactor. Since 2011, this work has accelerated to demonstrate the manufacture of components needed for the 600-MWe-and-larger units and design of critical and specialized equipment for reactor vessel support, seismic isolation, neutron detection, passive reactor shutdown, and remote inspection of equipment under sodium.91

Because China came relatively late to the fast reactor—and was also behind the curve for designing, constructing, and operating an industrial-scale unit—it can take advantage of lessons learned from earlier foreign projects. The design of the CEFR incorporated operational experience from previous projects on sodium fire mitigation, and the CEFR has better detection and alarm systems, a modern emergency ventilation system, sodium fire suppression equipment, graphite-based fire extinguishers, and steel covers and insulated concrete surface covers.92

China joined multilateral expert groups—the Generation IV International Forum (GIF), the IAEA’s International Project on Innovative Reactors and Fuel Cycle (INPRO), and the IAEA Technical Working Group on liquid metal fast reactors—to benefit from more experienced states’ advanced reactor development programs. GIF was established to support international cooperation on six reactor designs, including sodium fast reactors, and INPRO was established to encourage generic cooperation on reactor and fuel cycle innovations, including fast reactors. They were not, however, intended to develop or share confidential intellectual property, and individual members continue to focus on their own unique, proprietary, and, in some cases, divergent country-specific engineering solutions.

In December 2017, China inaugurated construction of a 600-MWe fast reactor that is scheduled to be finished in 2023. Some experienced fast reactor engineers outside of China suggested that the proposed five-year construction schedule is not realistic because China does not have enough fast reactor design, commissioning experience, and other resources to quickly build an industrial-scale reactor so soon after completing the CEFR. Other sources in China said that the 2023 deadline is considered by the government to be “flexible” due to the pioneering status of the project.93 CIAE itself is aware that the ambitious schedule—and perhaps even its value as a showcase for advanced technology—will be challenging, as Chinese firms are forced to manufacture critical equipment for the reactor before GIF can address related technical issues for the design of more advanced equipment.94 Chinese project engineers have likewise warned that the CEFR went over budget twice during implementation because critical components had to be procured from abroad, because China lacked fast reactor project management experience, and because Chinese engineers had few references for the integrated pool-type reactor design that had been chosen.95 Some experts interviewed for this report cautioned that the sooner China aims to break ground on the 600-MWe fast breeder demonstration reactor, the less confidence they would have that the project will be completed on schedule. Should China, in light of its limited experience with fast reactor engineering, form foreign partnerships to realize this project, the administration, oversight, and requirements of collaborative decisionmaking would inevitably cause delays.

When the State Council ordered a penetrating nuclear power safety review after the Fukushima disaster, experts identified safety design weaknesses in the just-commissioned CEFR. These included containment issues; inadequate decay heat removal from spent fuel in the case of a long-term loss of power; and loss of heat sink for design basis accidents. Separately, experts found weaknesses in defense against certain severe accident scenarios.96

Russian industry—which supplied a considerable share of the technology basis and key equipment for the CEFR—continues to contribute to China’s fast reactor program. The 2009 agreement to build the BN-800 in China is in abeyance,97 but China and Russia signed a nuclear cooperation agreement in November 2016 that included future fast reactor development collaboration.98

China has also cooperated with the United States on the development of closed fuel cycle technology related to the fast reactor. In 2006, the United States launched the Global Nuclear Energy Partnership (GNEP), a multilateral forum to cooperate on advanced nuclear power–related technologies. China joined GNEP the same year and, in 2007, the United States and China concluded a Bilateral Civilian Nuclear Energy Cooperative Action Plan meant to “collaborate on research to further develop advanced nuclear fuel cycles with the objective of nuclear safety and non-proliferation.”99 One working group concerned fast reactor collaboration, and it continued to convene during the 2010s. As part of this, China has enlisted the cooperation of U.S. national laboratories in areas including reactor core physics, modeling of fuel cycles, and development of fast reactor metallic fuel.

As previously discussed, the U.S. firm TerraPower agreed on the outlines of collaboration with CNNC and CIAE on the joint development of a fast reactor, the conceptual design for which relies on previous U.S. experience, principally at Argonne National Laboratory. The extent of U.S. cooperation with China in this field is subject to U.S. export control restrictions.100 Unofficial media have reported that U.S. export controls on sensitive technology were adjusted by the U.S. Department of Energy to permit sensitive but unclassified technology transfer from the United States to China for the TerraPower project.101 However, according to U.S. officials, security and nonproliferation concerns have prompted political directors in the U.S. government to occasionally discourage U.S. industry and government entities from contributing to some aspects of China’s fast reactor program.

Reprocessing

China’s assertion that it aimed to close the nuclear fuel cycle at the industrial scale meant that, at some point, it would construct facilities to reprocess its spent fuel, make new fuel using the recovered fuel materials—uranium and plutonium—and dispose of the residual wastes generated from reprocessing and fuel fabrication. In 2014, the Chinese government described the government’s policy on management of spent nuclear fuel:

China’s spent fuel management policy is to implement the reprocessing of spent fuel and to extract and recover uranium and plutonium materials, so as to achieve maximum use of resources, reduce the generation of high level radioactive wastes (HLW) and to ensure the safety of spent fuel management and the public safety, and to lower the risks to the future generations.102

When China chose Westinghouse over French firm Areva to provide the blueprints for future PWRs in 2006, it also took a step toward the realization of an industrial-scale reprocessing plant to follow the pilot plant then under construction at Jiuquan. Areva and CNNC concluded a memorandum to build a Chinese reprocessing plant based on Areva technology used in installations with a capacity of 800 MTHM per year (MTHM/y) in France and Japan.

Beginning in 2006, the two sides failed for a decade to agree on terms for this project, leading some Chinese experts to favor construction of a smaller plant using indigenous know-how. France and China differed over the price and French officials raised concerns about national security.103 U.S. government officials openly objected to China’s designs to establish a commercial-scale reprocessing industry, and discreetly urged France not to go forward with a bilateral reprocessing agreement that might involve the sale of Areva shares to CNNC.104

According to a Chinese executive, the Communist Party’s leadership formally approved CNNC’s industrial-scale reprocessing plans sometime in late 2014.105 Since then, technical discussions between French and Chinese government agencies and firms concerning details of the bilateral reprocessing project were conducted on the understanding that an 800-MTHM/y reprocessing plant using Areva technology would be erected by 2032 at one of a number of proposed Chinese locations, and that full-scale operation of the plant would commence by 2035.106

Senior executives from Chinese reactor-owning organizations said in November 2017 that China intends to carry out both the 800-MTHM/y reprocessing plant project based on foreign assistance and a 200-MTHM/y “indigenous and intermediate-sized” reprocessing plant. Both projects, they said, are called for under official central planning decisions covering the period 2011 to 2020, including the Thirteenth Five-Year Plan, and implementation is subject to ongoing deliberations of the Standing Committee of the State Council of Ministers. According to these officials, the State Council formally decided in December 2016 to make the necessary investments for both industrial-scale reprocessing plants.

Pre-construction site preparation activities began in 2015 on the intermediate-sized reprocessing plant in the Jinta district in Gansu Province, north of Jiuquan. Officials in 2016 described the intermediate-sized plant as having a design throughput of 200 MTHM/y and a completion date of 2025, five years later than originally foreseen.107

Spent Fuel

So far, virtually none of China’s power reactor spent fuel has been reprocessed, reflecting Beijing’s overwhelming focus on nuclear power plant construction and operation. Instead, China has taken action to store its spent fuel for at least two decades, primarily at the reactor sites. This is consistent with the management of spent fuel in many other nuclear power programs, and China is using technologies for spent fuel storage that are conventionally deployed worldwide.

By 2005, China had accumulated a total of 1,100 metric tons (MT) of spent fuel. By 2020, reflecting the dramatic increase in China’s reactor population, this stockpile should increase sevenfold.108 Nearly all of China’s power reactor spent fuel is being stored at the power plant sites.

Currently, over half of China’s installed nuclear capacity is based on a standard French PWR model. Spent fuel from these reactors is stored in water-filled pools designed to hold approximately ten years’ worth of spent fuel from normal operation. China is also building PWRs based on the U.S. AP1000 design. Spent AP1000 fuel will be stored in a water-filled pool with the same capacity of ten years of normal plant operation.109 Since 1992, China has operated a twin-unit Russian-design VVER PWR at Tianwan, which is also equipped with spent fuel pools. In 2016, these pools were reportedly nearly full and Russian industry was tasked with adding more storage capacity during ongoing construction of additional VVERs at the site.110 China’s first uniquely designed power reactor, Qinshan-1, has sufficient capacity at the site to store all spent fuel through 2025; two follow-on units, Qinshan Phase II, have sufficient capacity through 2022.111 Storage capacity at existing reactors has been expanded, and new PWRs are equipped with twenty years’ on-site spent fuel storage capacity.112

In addition to its growing number of PWRs, China is also operating a nuclear power plant called Qinshan Phase III, which is equipped with two CANDU 6 (Canadian Deuterium Uranium) pressurized heavy water reactors fueled with natural uranium. The two reactors discharge about 5,000 small bundles of spent fuel per year. These are stored initially in a water-filled pool with a capacity of just under 38,000 bundles, which is the amount of spent fuel discharged after about seven years of normal operation. Since 2008, China has been constructing a series of modular dry storage facilities at the site for the longer-term storage of this spent fuel. Each module has the capacity for 24,000 spent fuel bundles. China plans to construct a total of eighteen modules, assuring sufficient capacity to store spent CANDU fuel until at least 2042.113

China has also taken steps to store spent fuel away from the reactors. Both the pilot reprocessing plant at Jiuquan and the intermediate-scale reprocessing plant at Jinta are designed with head-end facilities to receive and store spent fuel prior to reprocessing. The head-end facilities at Jinta and/or Jiuquan may, in the future, be large enough to store several thousand metric tons of spent fuel and could, in principle, be continually expanded should China decide to move larger amounts of spent fuel away from reactor sites that are filling up.114

That option may be under consideration in light of recent political challenges China has experienced. In part related to political and regulatory developments after the Fukushima accident, Beijing has had difficulty securing approval from local and provincial authorities in eastern China to site future centralized spent fuel storage locations on their territories. During the 2000s, the spent fuel wet-storage capacity at Jiuquan was expanded from 500 MTHM to 760 MTHM, but its use was delayed by regulators, which threatened to suspend operations at the Daya Bay nuclear power plant for lack of spent fuel storage capacity. The emergency was alleviated by shunting spent fuel from Daya Bay to the nearby Ling Ao nuclear power plant.115 Before 2030, China will likely need additional storage space to accommodate spent fuel discharged from currently operating nuclear power plants.116

China’s future rate of spent fuel accumulation will depend on how long its existing nuclear power plants are operated, and on how many more nuclear power plants it builds. China expects to continue to add to its nuclear electricity generating capacity in coming years, but the government has not established firm planning targets for installed capacity beyond the end of the Thirteenth Five-Year Plan in 2020. Were China to expand capacity to 150 GWe by 2035, it might accumulate about 21,400 MT of spent fuel by then. If, instead, China expands capacity to 450 GWe, its accumulation would be perhaps about 29,400 MT by 2035.117 By comparison, the United States operated as many as 100 power reactors for over sixty years and its cumulative spent fuel inventory has reached about 70,000 MT.118 The total amount of power reactor spent fuel in the world is currently about 300,000 MT.119

The averted shutdown at Daya Bay over lack of spent fuel storage capacity has led reactor owners to consider the possible consequences of any future short-term bottlenecks and the need for China’s reprocessing plans to be realistic. It is obvious to Chinese planners that an aggressive reprocessing schedule would in theory take pressure off reactor owners and politicians to provide for additional interim spent fuel storage capacity.120 Independent of plans to provide for sufficient storage capacity, some reactor owners may experience logistic and regulatory complications arising from changes in in-core fuel management—implying that fuel will remain in the core for longer periods, which increases its heat load and alters its radioactive contents. Chinese executives privately express concerns that, while it proved relatively simple to move spent fuel from Daya Bay to an alternative location, a Chinese reactor owner might be hostage to commercial pressure from competitors, especially CNNC, in a different situation.121

Unlike Japan, South Korea, or Taiwan—where policymakers are under greater near-term pressure to secure adequate storage for power reactor spent fuel—China is a very big territory with many remote areas. For at least most of this century, China could technically manage all of its power reactor spent fuel by storing it at reactor sites and off-site locations, using water-filled pools followed by dry storage. On the basis of experience and licensing in other nuclear power programs, China could safely and reliably store its spent fuel without alteration through mid-century and for at least several decades beyond. At some future time, however, China will need to make policy and engineering decisions about disposing of its spent fuel in the long term.122

According to China’s nuclear technology development plan, “spent fuel reprocessing is the vital link in the closed fuel cycle, especially for the transition from an advanced thermal reactor to a fast reactor-based fuel cycle.”123 Should China set up a network of industrial-scale fast reactors, each might require an initial inventory of several tons of plutonium, most of which would be loaded into the core. Once the fast reactors begin operating, plutonium will be supplied to the system in two ways: by the reactors converting uranium-238 in driver and blanket assemblies in the reactor cores to plutonium-239 through neutron capture, and by the reprocessing of spent fuel from thermal reactors that continue to operate. Each fast reactor would provide more plutonium than it needs to operate; eventually, each will generate enough plutonium for the initial core of a new fast reactor. The rate of production of excess fissile material in the fast reactor system is called doubling time.124 This depends on variables including the total fissile material mass, reactors’ breeding ratio (the rate of plutonium production from fertile isotopes divided by the plutonium consumption),125 and the amount of plutonium losses during fuel fabrication and reprocessing. Doubling times might be as short as five years for some aggressive breeder reactor deployment scenarios or as long as twenty years in scenarios where the rate is comparatively relaxed. Some scenarios envisage fast reactors reducing existing plutonium inventories by “burning” more plutonium than they generate; very ambitious breeder reactor deployment scenarios call for deploying many reprocessing plants to accommodate projected plutonium demand. Chinese experts have derived numerous theoretical scenarios and calculations for both burning and breeding plutonium.126

In some scenarios, theorists postulate that a country like China might transition from a nuclear power system mostly based on PWRs to a system relying on fast reactors over a period of several or many decades. How quickly a country could effect that transition would depend on its technology resource base (in particular, its capacity to provide fuel cycle infrastructure including reprocessing and fuel fabrication plants), the rate of growth of its electricity demand, and other factors. Theoretically, if a number of nuclear power–producing states attempted to organize a coordinated global transition from LWRs to fast reactors, a sevenfold increase in reprocessing capacity might be required over half a century.127

In reality, no country’s nuclear energy program has so far deployed more than one large industrial demonstration fast reactor fueled with plutonium at any time, and a coordinated multinational deployment of fast reactors has never been attempted. Europe and Japan set up reprocessing plants in tandem with successive deployment of pilot and demonstration fast reactors, but the fast reactors were prematurely shut down or not built and the reprocessing plants were used instead to supply plutonium for MOX fuel for existing thermal reactors. Considering this experience, China would need to carefully match the supply of its future plutonium with its real plutonium demand.

Should China go forward with its plan to reprocess its spent fuel, it would follow in the footsteps of a number of other countries, including the United States, France, Germany, Italy, Sweden, Switzerland, Belgium, Netherlands, Russia, and Japan. Most of the world’s reprocessed power reactor spent fuel was handled at reprocessing installations in France. In the 1970s, French government–owned Areva established spent fuel reprocessing and MOX fuel fabrication as a commercial business activity in tandem with France’s decision to accelerate its construction of nuclear power plants. Beginning in the 1980s, Areva built a reprocessing plant complex at La Hague that currently has the capacity to reprocess 1,700 MT of spent fuel per year. As of 2005, about 90,000 MT of the 276,000 MT of spent fuel from civilian nuclear power generation had been reprocessed worldwide. Today, perhaps 120,000 MT in power reactor spent fuel has been reprocessed.128

All of the world’s industrial spent fuel reprocessing plants were designed for a technology called the Plutonium Uranium Redox Extraction Process (PUREX), which uses nitric acid to dissolve spent uranium oxide fuel and relies on organic chemicals to extract pure uranium and pure plutonium from the solution. This process was developed after World War II and adopted, beginning in the mid-1950s, over two decades by France, Germany, Japan, the UK, the United States, and the Soviet Union. PUREX succeeded in large part for three reasons: it demonstrated a high recovery rate for plutonium, thanks to the use of the low-cost organic reagent tri-n-butyl phosphate; it supported recycling of recovered uranium; and it solved certain waste management issues more effectively than other alternative processes.129

In the 1980s, when Beijing announced it would establish reprocessing infrastructure for its future power reactor spent fuel, China likewise intended to use PUREX technology and designed the pilot plant for PUREX. According to Chinese scientists, PUREX is preferred because it is well understood and is the global industry standard. For the same reasons, scientists say that China has also chosen PUREX as the technology basis for the 200–MT per year (MT/y) reprocessing plant now under construction.130

Should spent fuel reprocessing continue as an industrial activity throughout this century, however, PUREX may be replaced before or by 2050 by more advanced technologies for reasons of nonproliferation, economics, waste management, and environmental impact.

On security and nonproliferation grounds, a disadvantage of PUREX is that it generates pure separated plutonium from spent fuel. To address this concern, French scientists developed a process for the co-extraction of actinides (COEX) to retain a uranium/plutonium mixture through the end of the process, in some variations creating a uranium/plutonium blend feedstock for MOX fuel fabrication.131 This or similar process technology may be designed into new reprocessing plants—including a plant that Areva may build in China—though the COEX process is not without technical challenges.132

Current R&D efforts to go beyond PUREX in China are driven by ongoing improvements and technological developments in reactor technology and power reactor fuel. PUREX was not designed to treat more challenging spent fuel types, such as fuels with high plutonium content, non-oxide matrices, and high discharge burnup (the amount of energy generated in a reactor per initial mass of fuel). The global nuclear industry has over several decades—especially since market forces began encouraging industry to use resources more cost-effectively—increased the burnup levels of power reactor fuel. For mainly economic rationales—reducing the amount of downtime for refueling, reducing the amount of fresh fuel that must be loaded into reactors, and reducing the amount of spent fuel that must be discharged to generate a given amount of energy133—burnup has risen from mid-30 GW days per MT of fuel (GWd/MT) to nearly 50 GWd/MT today.134 In the future, the burnup level for some LWR fuels may approach 90 GWd/MT, implying that, by mass, the fuel would be producing three times the amount of energy than during the early years of nuclear power generation.135

As burnup increases, spent fuel exhibits higher concentrations of a large variety of fission products, making it more difficult to reprocess. There may be buildup of particulates that resist dissolving. Reprocessing very high burnup fuel may require facilities equipped with additional neutron shielding, designed for a higher rate of solvent degradation, higher operating temperatures, and different materials and processes for high-level waste (HLW) treatment to cope with higher decay heat, higher neutron outputs, and higher inventories of heavy nuclides. China’s nuclear industry and R&D sector are fully aware of these trends. Chinese reactor owners frequently cite ongoing increases in the burnup of spent fuel as a factor in urging policymakers to ensure that, in parallel with planning for reprocessing, China provides for sufficient interim spent fuel storage capacity. At the R&D level, Chinese experts are exploring complex separation scenarios related in part to anticipated future fuel strategies and technologies.136

Partitioning and Transmutation

Chinese experts frequently say that waste management, especially partitioning and transmutation (P&T), is a key rationale for both reprocessing and fast reactor deployment.

The goal of P&T is to change the long-lived actinides into fission products and long-lived fission products into significantly shorter-lived nuclides, creating nuclear waste products that decay in a few hundred years compared to untreated waste that would remain radiotoxic for over 100,000 years. If successful, P&T would also permit the reduction of HLW inventories and the heat load of geological repositories,137 and eliminate most of posterity’s burden for managing today’s waste from nuclear electricity production. In the Chinese view, “For advanced reprocessing of future used fuels, the objective is not only to recover plutonium and uranium, but also to manage actinides and fission products.”138

Closed fuel cycle technologies are intended to dramatically reduce the radiotoxicity, or the hazard to human cell tissue, posed by spent fuel. Plutonium is the main contributor to long-term radiotoxicity in spent fuel and it can be efficiently removed using PUREX. Other long-lived and poisonous radionuclides that are currently disposed of as waste from PUREX reprocessing include the so-called minor actinides (MA), of which neptunium, americium, and curium are the most significant. Removing the plutonium from spent fuel can reduce the radiotoxic inventory of spent fuel by a factor of ten. If MA are separated and then burned in a fast reactor, the reduction factor might be higher than 100. Neptunium can be removed by adjusting PUREX, but not americium or curium.139

However, the nuclear science challenges of P&T are extremely formidable. Recovery of MA is difficult because the chemical properties of these elements are highly similar under conditions that would likely be encountered in a solvent-extraction process. Selective separation of americium and curium from lanthanide fission products, and separating the americium from the curium, are foreseen in some advanced scenarios but the similar chemical behavior of the elements involved make these challenges among the most difficult in advanced reprocessing.140

A number of processes have been developed that go beyond PUREX to facilitate P&T, but these will only be relevant for nuclear power applications if they can be made to work at the industrial scale and if fast reactor technology is commercialized.141 Scientists hope that the world’s extensive cumulative experience with PUREX will lead researchers to design separation systems likewise based on solvent extraction that will facilitate industrial-scale P&T. Research on the engineering of systems for industrial scale application is being considered.142

Caution, however, is warranted because MA separation has been the subject of active research for half a century. Researchers need better engineering tools, including spectroscopic advances, supported by computational techniques to develop processes that are simple and economical enough to be applicable for nuclear power.143 Two decades or more may be required before nuclear power might benefit from this P&T research.144

China and Advanced Reprocessing

Chinese research on P&T started during the early 1980s, and scientists more recently began R&D on an advanced PUREX process, in part to meet the challenge from spent fuel with higher burnup levels.

A key element of Chinese advanced PUREX research is the application of salt-free organic reagents to improve PUREX. One focus is on problems in PUREX related to the behavior of technetium in the dissolved spent fuel that can lead to excessive plutonium accumulation and failure of separation of plutonium and uranium.145 Another area of Chinese research is to achieve efficient separation of neptunium from the plutonium product stream. Some Chinese efforts on separation chemistry have concentrated on recovery of all actinides—uranium, plutonium, neptunium, americium, and curium—as a group, leaving the shorter-lived heat-emitting elements—cesium and strontium—in the HLW. China has focused on the use of so-called trialkyl phosphine oxides (TRPO) to achieve total actinide recovery from HLW generated from PUREX reprocessing. Some experiments were carried out using this process to treat HLW generated by China’s nuclear weapons program. More recently, China has also designed a process for the separation and recovery of actinides and lanthanides, including separating and recovering strontium from HLW.146

China is also working on the separation of actinides from lanthanides, and has achieved lab-scale success using chosen extractant organic chemicals.147 But researchers have also experienced degradation of extractant chemicals from high radiation fields, and this problem must be addressed before China can consider moving toward industrial-scale applications.148 The Chinese TRPO process was tested successfully in Europe, but it was judged to have drawbacks including extra process steps that may discourage industrial application, certain fission products interfering with the separation, and high nitric acid concentrations in the actinide/lanthanide mixture.149

Pyroprocessing

Scientists planning for a closed fuel cycle anticipate that after aqueous PUREX reprocessing is mastered, China will develop and deploy a nonaqueous technique called pyrochemical processing, or pyroprocessing, to supply recycled fuel for future fast reactors. Pyroprocessing has been in development since the 1950s, originally by the United States and the Soviet Union in tandem with their fast reactor programs, and is now also being researched and developed in South Korea, Japan, India, and Europe.

In pyroprocessing, spent fuel is chopped, heated, and turned into a powder, which is subjected to high heat that burns off volatile fission products (krypton, xenon, iodine, and cesium). The powder is transformed into a metal that is placed into a bath of molten salts, such as lithium chloride or potassium chloride. The bath with the metallic fuel material is then subjected to an electric current (so-called electrorefining process), and the metal dissolves and separates into component stages. Pure uranium collects at a steel cathode immersed in the bath, and the transuranic material (plutonium, neptunium, americium, and curium) and fission products (cerium, neodymium, and lanthanum) are removed. The uranium is brought to a casting furnace where it is used to make new fuel. The transuranic elements and fission products can be conditioned for disposal in a geological repository or also processed in a casting furnace to make fuel for a fast reactor.

Pyroprocessing chemistry is well-understood. Since metallic fuel would likely be used in future fast reactors because it is more efficient than oxide with respect to heat conductivity and breeding ratio, pyroprocessing may be appropriate since it involves handling of metals at high temperatures. In the GIF program, advocates assert that pyroprocessing has specific advantages for advanced closed fuel cycles. These include: integration of reactor operation, reprocessing, and fuel fabrication; resistance of molten salt and liquid metal solvents to radiation damage for high burnup fast reactor fuels; reduced quantities of waste; and inherent actinide partitioning. The radiation resistance of molten salt implies that fuel cooling times may be shortened. Integration of fuel cycle process steps may lead to more compact installations. Criticality dangers might be reduced because the process will generate relatively impure product fractions.150

There are also potential drawbacks to pyroprocessing. These include: possible misappropriation of separation technology to produce pure plutonium; the aggressive behavior of molten salts and liquid metals; the material science and maintenance challenges concerning equipment in a commercial-scale plant that must withstand high operating temperatures between 400 and 1,000 degrees Celsius; and the daunting engineering challenges of adapting what has been, until now, a limited-batch process requiring a highly pure environment to handle industrial quantities of spent fuel.

China’s recent engagement in this field has been generic compared to the experience accumulated by the United States, South Korea, and Russia. China has, so far, not processed irradiated nuclear fuel in specially designed pyrochemical research installations. Following the establishment of GNEP in 2006, China and the United States began cooperating on the development of high-burnup fast reactor metallic fuels, casting technology for uranium/plutonium fuel, and pyroprocessing flow modeling.151 Some Chinese experts have suggested that Beijing aims to set up a pyroprocessing facility for spent fuel by 2030 or 2035.152 To date, however, most Chinese pyroprocessing research is academic and concerns, for example, measurement of basic parameters including on uranium in molten chloride salts, simulations of fuel dissolution in molten salts, and properties of molten salts. China is currently not operating any pyroprocessing installations.153 Because CNNC has a monopoly on China’s aqueous reprocessing activities, it was rumored in 2017 that CGN might seek pyroprocessing R&D partners in South Korea; this was denied by CGN officials.154

Other Advanced Fuel Issues

Should China build and operate fast reactors in addition to its PWRs, it will have to set up infrastructure dedicated to producing fast reactor fuel and reprocessing the spent fuel. Because of differences in radioactivity and isotopic composition, this fabrication and reprocessing activity would be in addition to and separate from China’s ongoing fabrication and reprocessing of spent fuel from PWRs. If China deploys a large fast reactor in the near term, it might reprocess the spent fuel using currently available aqueous technology.

MOX Fuel Fabrication

Unlike LWRs, in which neutrons emitted by the fuel are slowed down by water to increase the probability that they will cause an exothermic fission reaction, breeder reactors rely instead on the greater amount of energy contained in fast neutrons. Sustaining a chain reaction in a fast reactor requires fuels richer in fissile material. In most fast reactors, highly enriched uranium (HEU) or plutonium is used. The fuel is normally either metal alloy or MOX. Russian fast reactors have operated mostly using metallic HEU fuel. Fast reactors in France and Japan have instead used MOX fuel.

MOX fuel currently accounts for about 5 percent of the world’s LWR fuel. So far, about 2,000 MT of MOX fuel has been used in about forty of the world’s 450 power reactors, mostly in Europe, consuming about 10 MT of plutonium per year. MOX use in LWRs has been inhibited by cost compared to natural uranium fuel. Penalties include more complex logistics that are required by the fuel’s radioactive profile, which includes decay of some plutonium into americium (a neutron poison that emits gamma radiation). MOX fuel has been produced at an industrial scale in Belgium, France, and the UK, but it is likely that only France will make MOX fuel for LWRs during the 2020s, joined perhaps by Japan. Russia will make MOX fuel for fast reactors only.

China could, in principle, replicate and build on the experience of these, but it has far to go. China elected to begin operating the CEFR initially with HEU metal fuel provided by Russia, followed by eventual loading of MOX fuel, which would also be used for follow-on Chinese breeder reactors prior to an anticipated transition to metallic fuel.

In 2013, consultants told the Chinese government that China was decades behind other countries in establishing the technical basis for a nuclear power closed fuel cycle.155 For political reasons, China could not implement a 2010 bilateral agreement with Belgium to replicate its MOX fuel know-how.156 Without it, China is relying on laboratory equipment installed in 2003, comprising twelve glove boxes and Chinese-made equipment for mixing uranium and plutonium powder, compacting the powder into fuel pellets, and sintering the pellets. This plant was supposed to produce MOX fuel for the CEFR beginning in 2010.157 As of early 2017, China has not loaded any MOX fuel into a PWR, and it has used very little, if any, in the CEFR. The small scale of China’s MOX fuel fabrication line makes it difficult to assure homogeneity in a large batch.158 To operate a 600-MWe breeder using MOX fuel, CNNC would need a license to build a MOX fuel fabrication plant with a design throughput of 20 MT/y.159

Beyond challenges related to MOX fuel, China’s transition from oxide to metallic fuel for fast reactors might begin around 2030 with an initial fabrication capacity for zirconium-plutonium-uranium fuel of 6 MT/y, about a decade after China sets up a pilot fabrication facility for this fuel.160 Under GNEP, China pursued collaboration with U.S. national laboratories in this direction.161 Following from China’s November 2016 bilateral nuclear cooperation agreement with Russia, it is possible that the two counties may cooperate to develop metallic fuel for China’s fast reactor program. In principle, China could also cooperate with U.S. industry and laboratories interested in the development of metallic nuclear fuel.

Aqueous Fast Reactor Spent Fuel Reprocessing

There are considerable differences between the reprocessing of spent LWR fuel made of uranium oxide and the reprocessing of MOX fuel or metallic fuel that has been irradiated in fast reactors. The plutonium in fast reactor spent fuel can account for between 25 percent and 30 percent of the heavy metal content, compared to less than 2 percent in spent LWR fuel.162

Reprocessing fast reactor fuel is beset with a number of specific challenges. High-burnup oxide fuel with high concentrations of plutonium is kinetically and thermodynamically more difficult to dissolve, and the plutonium chemistry interferes with solvent extraction. These fuels can form cruds of noble metal alloys that do not dissolve. Likewise, plutonium-rich particulates from broken up spent fuel may emulsify and pose the threat of a criticality accident. At the laboratory scale, the danger of a serious criticality accident can be far more easily managed than in an industrial-scale installation holding bulk amounts of plutonium. The higher the burnup, the more difficult managing these issues can become. If highly radioactive matter remains undissolved during the initial processing stage, the heat it emits can damage plant equipment if particulates accumulate downstream. Not removing metal cruds will also reduce the efficiency of chemical separation.163

Compared to LWR fuels, fast reactor spent fuels also exhibit a higher concentration of fission products. Most can be removed during product purification, but some highly radioactive elements are more difficult to remove. Finally, care must be taken to manage a higher level of solvent degradation during the reprocessing of spent fast reactor fuel, as well as the threat that organic materials requiring removal from the process stream may form explosive nitrate compounds; this problem has caused accidents in Russia and the United States.164

A limited amount of fast reactor fuel with high plutonium content has been reprocessed in France, the United States, India, Germany, Japan, and Russia. All these countries but Russia used roughly the same chemical process. R&D on fast reactor fuel reprocessing may have accelerated over the last decade in response to GNEP and GIF international programs. Ongoing work includes developing processes that go beyond PUREX chemistry. As with pyroprocessing, the major challenge for aqueous reprocessing of fast reactor fuel will be to arrive at an industrial-scale process that is economical, efficient, and reliable.

Several decades of work may be necessary to reach that goal and, so far, China has little or no direct experience in reprocessing fast reactor spent fuel. China might instead focus on non-PUREX-type fast reactor reprocessing systems, especially pyroprocessing. But this technique, too, is far from being ready to deploy to treat large amounts of spent fast reactor fuel. In recent years China has foreseen possible construction of a plant to reprocess spent MOX fuel with a capacity of 50 MT/y to match the requirement for the 600-MWe breeder reactor now under construction.165

Recycling of Reprocessed Uranium

In addition to plutonium, China also aims to reprocess spent fuel to recover uranium.

Reprocessing spent LWR fuel recovers both plutonium and uranium. Beginning four decades ago, a number of nuclear power–generating countries experimented with recycling reprocessed uranium (REPU) in their reactors. The amounts of REPU have been growing in step with the amount of spent fuel that has been reprocessed. As of about 2010, the total amount worldwide is estimated to be in the tens of thousands of metric tons.166 However, the amount of REPU that is recycled is relatively modest. Most is stored, but its use as nuclear reactor fuel—including at an industrial scale in LWRs—has been technically demonstrated. Because REPU contains isotopes that are neutron poisons and emit high levels of gamma radiation, however, use of the material as a commercial fuel raises its effective cost, especially for reactor owners that want to increase the level of fuel burnup. Most countries, therefore, do not aggressively recycle their REPU but consider it to be a future potential asset that would appreciate in value should the price of uranium increase relative to REPU processing and storage costs. For many years, the behavior of reactor owners concerning use of their REPU has been opportunistic: interest in recycling REPU appears positively correlated with concern about the security of uranium supply.167

For decades, China made no firm plans to use REPU in its nuclear power program pending the introduction of spent fuel reprocessing.168 In September 2016, leading Chinese nuclear firms signed a memorandum of understanding with Canadian counterparts to design, market, and build a 700-MWe power reactor intended to use REPU as fuel. The reactor design would be a more advanced version of a standard pressurized, heavy-water-moderated-and-cooled power reactor built in Canada and elsewhere, including two units operating in China since the 2000s. According to the Canadian vendor, China would build an initial two reactors; each would use the REPU recovered from the reprocessing of spent fuel from four Chinese PWRs.169 Chinese experts expect that the foreseen commercial contracts for this project will include transfer of the ownership of technology for these reactor systems to China.170 Officials close to this project said in 2016 that the spent REPU burned in the Canadian reactors would eventually be used as fuel for one or more Chinese fast reactors, pending the establishment of industrial-scale technology in China for the reprocessing of this spent fuel.171

High-Level Waste Disposal

Regardless of whether China elects to reprocess its PWR spent fuel, it will need to dispose of HLW. China’s nuclear waste repository program resembles programs in other countries. Policymaking for nuclear waste disposal is in the hands of central government bodies: NSSA is the regulator, CNNC is designated as responsible for constructing and managing the repository, and a scientific body, the Beijing Research Institute of Uranium Geology, is in charge of project-related R&D. So far, China has conceived of the project to permit the repository to accept both spent fuel assemblies as well as vitrified reprocessing wastes, from both defense and civilian activities. The basic concept is that waste packages will be disposed of in horizontal shafts connected to tunnels bored into the repository site.

In 2003, after canvassing several possible locations in China for a repository, the government began focusing efforts to establish a geological repository for this waste in granite medium at Beishan in Gansu Province, a remote territory near the Jiuquan complex. During the 2000s, China set 2020 as the target for finishing the conceptual design for the repository.172 In 2012, after the United States decided to abandon its Yucca Mountain project to dispose of power reactor spent fuel, China expanded the site selection for its future HLW repository to a total of twelve candidate sites. Clay was added to granite as a possible repository medium, and a decision on site selection was foreseen in 2020.173

Before repository construction for the selected site can be licensed, China must finish a program of borehole testing, site selection, geological surveys, and studies on groundwater and radionuclide behavior in disposal media. China must also select a source for the bentonite rock that has been selected as a buffer medium for the repository. China plans to technically characterize waste packages, demonstrate the disposal technology, and build a site-specific underground laboratory sometime after 2020.174 Until the repository is constructed and licensed to accept spent fuel, vitrified reprocessing HLW, and other forms of HLW, China can be expected to store all spent fuel and vitrified waste for an interim period.

Other Nuclear Power Technologies

In addition to fast reactors and their associated fuel cycle technologies, China has invested in other nuclear technologies that could be deployed at a future time for power generation. The designs offer a variety of advantages, including passive safety features, deployment versatility, waste reduction, and lower coolant pressure. All of these reactor types would require the development of specific nuclear fuel management and/or processing technologies. Especially should China halt or slow down the forced development of fast reactors and reprocessing in the near term, China’s nuclear technology focus in the 2020s and beyond may change and evolve, as new technologies emerge and attract interest while other avenues currently being pursued lose traction for technology-driven, political, and economic reasons. In recent years, Chinese R&D organizations and industry have prominently invested in the following future options.

Molten Salt Reactor

China initiated an R&D project during the 1970s to develop a molten salt reactor (MSR) but it made little progress for many years because potentially showstopping materials challenges quickly arose.175 Beginning in 2011, CAS, which had been initially involved in the MSR exploration, resumed R&D in this field. It currently sponsors a project led by the Shanghai Institute of Applied Physics. If successful, this project will design and build a number of small experimental and pilot units over the next two to three decades, beginning with a pebble-bed reactor that operates on an open fuel cycle using solid fuel. Far more challenging are Chinese aspirations to develop and deploy liquid-fueled reactors that breed uranium-233 from thorium and operate on a closed fuel cycle. In any case, project officials caution that it may take until 2035 or later before a Chinese MSR would possibly operate for industrial-scale power generation.176

The MSR is a design that uses molten salt as the reactor coolant. The reactor operates at atmospheric pressure (sparing the technical and safety issues that derive from the enormous pressures reached in LWR systems), but at a higher temperature than LWRs, about 700 degrees Celsius. There are two design concepts, one based on solid fuel and the other on liquid fuel—China is interested in both. For the solid fuel design, which calls for tiny fuel pebbles, the salt is comparatively easy to handle using reactor equipment made of standard stainless steels. For the liquid fuel concept, there are complex corrosion challenges related to molten salt.

The MSR’s attributes and challenges will not allow it to replace the LWR at any foreseeable future time. CAS is focused instead on smaller, modular units that may be appropriate for power generation and would include a turbine generator requiring no coolant water.177 The MSR might, therefore, eventually be suitable for deployment in less-developed and drier regions in central and western China where, in the aftermath of the Fukushima accident, concern has been voiced that not enough local water would be available to assure safe LWR operation.

The CAS-sponsored group is beginning with a comparatively simple pebble-bed, solid-fueled reactor. A waste form for a once-through fuel cycle for this reactor is currently being studied. Unresolved issues concerning a liquid-fueled MSR are far more complex. Before such a reactor could be licensed, much work is needed concerning environmental impact; reactions involving molten salt; and pyroprocessing of the spent fuel and cleaning of the molten salt inventory in the reactor. It is not certain to Chinese experts how waste from a liquid-fueled reactor with a closed fuel cycle would be managed. Should China solve that problem inside two decades, the MSR may have a future impact on the direction of China’s fast reactor R&D, with a design that can burn actinides from spent LWR fuel. But Chinese scientists caution that, even if successful, a thorium/uranium–fueled MSR design may not be in a position by 2050 to rival the population of LWRs and perhaps fast reactors operating on uranium/plutonium fuels—any contribution the MSR would make in this area would be additive.178

The CAS group envisages the MSR to load thorium in the molten salt and breed uranium-233 by neutron capture. The fissionable uranium that is created and meant to be recycled would be separated by on-line pyroprocessing—a technique that poses considerable difficulties for separating uranium from thorium, including for reasons of chemistry, radiation resistance, compactness, exclusion of reactor moderator agents, compatibility with the molten salt carrier, and nonproliferation.179 For the Chinese MSR project, a pyroprocessing scheme has yet to be technically conceptualized.180

ADS and Thorium

China is also interested in developing a so-called Accelerator-Driven System (ADS) using a powerful particle accelerator to transmute actinides and breed uranium-233 in a thorium blanket that would undergo fission and generate power. In principle, the high-energy neutrons generated in a particle accelerator by bombarding target materials could be fired at other targets such as actinides.

ADS was included in China’s National Basic Research Program (the so-called 973 Program) in 1999 after initial studies were carried out between 1996 and 1999. CIAE and the China Institute of High Energy Physics (IHEP) carried out a five-year program on the physics and technology for ADS, and then built an experimental platform. According to one IHEP scientist in 2011, China is “still in the phase of basic research and pre-research for key components” of ADS.181 He said that China will launch a three-phase project, beginning with a ten-year effort to build a high-power accelerator and associated test equipment, followed by construction of a prototype ADS and a 30-MWe reactor and initial transmutation experiments by 2035, and finally building a “full-size industrial demonstration 800-MWe power reactor driven by a 10-MWe beam accelerator” before 2050. Achieving this program, he said, “will take thirty years.”182

More recently, the project timetable for this project has been shortened to allow for completion of a demonstration facility by 2032, including a reactor with a rating of over 1,000 megawatts of thermal energy (MWt) capable of generating electricity and processing nuclear power spent fuel and/or HLW. The challenges are daunting and include the target material, the reactor blanket, waste separation, accelerator engineering, and ensuring system reliability at an industrial scale. In March 2016, CAS and nuclear power plant owner CGN—which aims to challenge CNNC’s effective spent nuclear fuel processing monopoly—announced an agreement to cooperate in this field.183

According to CAS scientists, currently there is “no existing model in the world” for what China is trying to accomplish on ADS.184 China is not alone in researching ADS for power applications but the results concerning industrial applications have so far been modest. Accelerators have been designed that operate at only a small fraction of the beam strength necessary to build and operate an ADS functioning as a commercial-scale power reactor.185 Other countries are continuing with ADS research that has been underway for several decades. Norway, which has large thorium reserves, has been doing thorium-plutonium fuel research for power applications. It concluded in 2008 that industrial application of thorium-based fuel cycle technology including ADS might well be possible in coming decades, but warned that substantial resources (measured in billions of U.S. dollars) would have to be invested to overcome economic disincentives and technical challenges.186

Alternative Fast Reactor Designs

As part of the CAS ADS project, China is pursuing research on a lead-cooled fast reactor. CAS has proposed this type of reactor as the reference reactor for a Chinese ADS system, in three consecutive phases: 1) design of a 10-MWt research reactor by about 2020; 2) development of a 100-MWt experimental reactor during the 2020s; and 3) development of a 1,000-MWt demonstration reactor through the end of the 2030s. Until now, China’s lead-cooled reactor activities have not been prioritized on par with sodium-cooled fast reactor development.

In 2006, U.S.-based company TerraPower launched an initiative to license and build a proposed so-called traveling wave reactor. The initial version of the reactor called for a core of HEU fuel to undergo fission in a “traveling wave” pattern from top to bottom over a period of several decades, during which time all the fuel would remain in the core; thereafter, it would be removed and disposed of in a repository. The concept was intended to address concerns that spent fuel from conventional reactors, including fast reactors, would be a source of plutonium that could be diverted for nuclear weapons. In 2010, facing licensing difficulties in the United States and searching for a location with required infrastructure to prove that the reactor design was feasible, the company focused its attention on setting up a project in China with the cooperation of Chinese industry and government and supported by the U.S. government.

Since then, TerraPower has significantly altered its reactor concept following discussions with China’s nuclear industry to accommodate the limitations of current technologies, including with respect to materials requirements, possible know-how classification issues in the United States, and the engineering preferences of Chinese organizations.187 In 2015, TerraPower and CNNC agreed on the outlines of a project to build a reactor in cooperation with China’s fast reactor program. The arrangement would call for CIAE to develop the fuel and the reactor core for a pool-type 600-MWe power reactor, for which CNNC would be architect and engineer.188

This proposed reactor is a sodium-cooled fast reactor that would initially operate using driver fuel assemblies containing enriched uranium that breed plutonium in a uranium-238 blanket surrounding the core. The reactor would be shut down for one to two weeks per year to shuffle fuel assemblies to optimize operating and safety conditions. The core of the reactor would be replaced every ten years. The irradiated fuel removed from the core is to be re-clad and reused to drive up to three more reactors. The reactor concept would result in less spent fuel than would be generated in an LWR and, according to TerraPower, the spent fuel would be disposed of in a repository rather than reprocessed.189 TerraPower says that the reactor system is designed to use either depleted uranium or natural uranium but, in principle, it could also use spent PWR fuel in the future.190

The project draws upon the experience of fast reactor technology development in the United States. Some U.S. experts said that if the project goes forward in the near term, licensing may pose a challenge because there are no international design review criteria. As discussed above, some unofficial reports since 2015 speculated that the TerraPower project would be sited at Xiapu in Fujian Province and built after the CFR-600.191

High-Temperature, Gas-Cooled Reactor

Beginning in 1986, China’s 863 Program included the development of a high-temperature gas-cooled reactor (HTGR) for power generation and process heat applications. On the basis of technology acquired from Germany—including spherical fuel element production—Tsinghua University in 2012 began operating a small pilot high-temperature reactor, HTR-10, north of Beijing. This was followed by an ambitious project to set up a series of twenty bigger modular units to demonstrate the HTGR’s viability for large-scale power generation.